Technology & Materials

Our boards are built with high-end machinery and prime-quality materials, delivering a high quality, high performance final end product.

From the cutting machine to resin and fiber, we use the best materials in both internal or external production contracts.

|

|

CNC AKU SHAPERAKU is the only CNC system made exclusively for shaping boards. AKU cutter reverses direction for each side of the board (up to 140˚ around blank), providing extremely accurate and symmetrical rail cut. With an Aku Shaper Machine on site, we offer leading edge blank cutting services for any type of surf, kitesurf, SUP and wakesurf boards. Aku Shaper allows fast production with precision, minimizing operating errors and delivering pre-shapes that require minimal finishing work.

|

|

TOP QUALITY BLANKS

We use first quality foam blanks from different producers around the globe. Arctic and Teccel foam comprise the wide range of sizes, weights, stringers and rockers that we use to build homogeneous and durable final products.

|

|

Hexcel FiberglassSpecifically designed for surfboard making, Hexcel is the reference fiberglass product used by professional boardbuilders worldwide. We use Hexcel fiberglass in any kind of boards to get excellence in resistance and durability.

|

|

|

Aerialite fiberglassAerialite is quality crafted in the USA by BGF Industries. It is non-toxic, clear, strong, easy to use and really white. A fiberglass you can rely on.

|

|

|

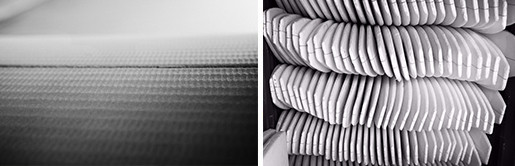

biaxial fiberglassBiaxial fiberglass provides higher strength to weight ratio. It also tons down the 'chatter feeling' some boards tend to have at high speed. For stronger boards that feel fast and responsive under your feet. |

|

|

carbonCarbon patches are meant to strengthen specific areas of the board, most affected by foot pressure and impact. Usually added over fiberglass, this material prevents severe deterioration and increases durability.

|

|

|

vector netGreat for increasing damage tolerance of a laminate and increasing stiffness. The diamond pattern weave provides a high level of break and buckle resistance while maintaining a natural and lively flex pattern. Lightweight mesh which makes the material very easy to laminate. |

|

|

Silmar ResinSilmar Resin is a standard reference in the board manufacturing industry. Shining, consistent and UV resistant. |

|

FCS FinsFCS has one of the most diverse fin collections in the market with different fin systems models (X2, II, Fusion and Origin). We place FCS Fin Systems in any board accordingly to each client or brand standards and preferences.

|

|

Futures FinsFutures Fins are known as one of the most user friendly and strongest removable fin system available in the market. With performance similar to glass-on fins, Futures Fins offer plugs customizable colors.

|